How a carbon capture system works—and its dangers

Carbon capture has become the divisive hot topic in Illinois climate policy over the last year. The Inflation Reduction Act (IRA) included substantial subsidies for carbon capture that have created an industry gold rush looking to build and operate carbon capture systems (CCSs), carbon pipelines, and carbon sequestration. One such project proposes to put carbon capture on Illinois’s largest coal-fired power plant. It is being led by UIUC’s Prairie Research Institute (PRI), but there are reasons to be skeptical of the project.

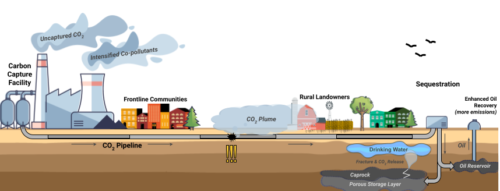

Carbon capture and storage is the process of isolating carbon dioxide (CO₂) either at a source (power plant or factory) or directly from the air. Then the captured CO₂ is transported, often through a pipeline, and stored, usually in underground geological formations such as saline reservoirs or depleted oil reservoirs.

When environmentalists discuss carbon capture as a climate solution, they’re talking about deploying the technology in “hard to decarbonize” sectors, such as steel, cement, or long-distance transportation. These are industries where producing carbon is nearly inevitable, so capturing carbon is one of the few possible solutions. Coal- and gas-fired power plants are not “hard to decarbonize”—we just need to use alternate energy sources. The fossil fuel industry talks about carbon capture as the lifeline that’s going to keep the polluting power plants around as long as possible. No serious climate champion is thinking about carbon capture as a solution if it means sticking carbon capture on coal or natural gas power plants.

Nevertheless, the IRA subsidies are triggering an industry bonanza, and at the center of Illinois’s carbon capture debate is the Prairie State Coal Plant in Marissa, IL. This massive 1,600-megawatt coal plant is operated by the Prairie State Generating Company and owned by nine public power agencies that serve 277 municipal utilities and rural electric cooperatives across eight states. It is Illinois’s biggest coal-fired power plant, the seventh-largest carbon polluter nationally, and a notable source of other pollutants such as nitric/nitrogen and sulfur oxides, as well as coal ash. The 2023 Out of Control report states that the Prairie State Coal Plant contributes to 76 premature deaths annually due to air pollution, yet it has operated for over a decade without an approved Clean Air Act permit.

Illinois’s Climate and Equitable Jobs Act requires municipal coal plants, including Prairie State, to be 100-percent carbon-free by 2045, with an interim emissions reduction goal of 45 percent from existing emissions by no later than 2038. A proposed federal rule may require closure even sooner if carbon emissions aren’t nearly eliminated. The coal plant’s only lifeline is installing a CCS. PRI is working very hard to extend the life of the Prairie State Coal Plant in this manner. It is writing the plan for how to install carbon capture on the coal plant; doing the upfront feasibility studies; applying for federal funds; and even submitting sequestration permit applications on behalf of the coal plant.

While capturing all of the Prairie State’s carbon emissions sounds great in theory, there are a multitude of problems with CCSs, particularly when deployed on coal plants. Operating a CCS on Prairie State will require a significant amount of energy, called a parasitic load. PRI is proposing that Prairie State create a new tie-in to the grid just to power the carbon capture equipment. That is, it will make dirty energy only to use a potentially large portion of that energy to eliminate its carbon emissions (but not other emissions).

Operation of the CCS will also need a substantial amount of additional water, both for operating the new power plant and for the carbon removal process. A CCS unit at Prairie State would use additional water from the Kaskaskia River, a consideration that is not thoroughly examined in any of PRI’s studies, nor has it been discussed with the communities that rely on the Kaskaskia River for drinking water.

Even if all of the carbon dioxide is captured (which is doubtful), the carbon capture technology does nothing to stop most other pollution created by burning fossil fuels, including smog-creating and health-harming airborne pollutants and coal ash. With increased water demands, continued coal ash production, and health-harming air pollution, extending the life of the power plant has a real cost. Fighting to keep Prairie State running is the same as fighting to keep another decade or more of that pollution. In their Front End Engineering Design (FEED) study, PRI contemplated how the Prairie State Coal Plant could approach the air permitting for the CCS facility to expedite and streamline the process without consideration of harmful co-pollutants and cumulative impacts of air pollution from both facilities.

The carbon captured at the Prairie State Coal Plant will need to be stored somewhere. PRI is proposing to store the carbon at an injection site a few miles north of the plant. Carbon sequestration itself is not without risks. CO2 leaking from underground storage can alter water chemistry in drinking water aquifers, potentially releasing toxic pollution like arsenic and lead. Any CO2 that leaks from the sequestration site will undo the benefit of capturing that carbon.

If all of this sounds expensive, that’s because it is. The price tag for capturing carbon for half of Prairie State is estimated at $2 billion up front and $175 million annually. That doesn’t include the costs of sequestration. Prairie State is seeking a third party to construct and operate the CCS, expecting to pay for the project with taxpayer-funded federal incentives. Additional economic analysis of the project’s costs should be done, given the history of failed CCS projects, including the recent Texas Petra Nova project that cost over $1 billion, captured just seven percent of its total emissions, and closed after four years. Similarly, a detailed analysis should be done to consider the potential for Prairie State Coal Plant owners to invest in clean energy technologies and achieve the same climate benefits without the pollution.

The voice of the public is missing. The studies, solicitations, permits, expenditures, and decisions to advance CCS at Prairie State Coal Plant have been made without involvement or input of the owner-members of the 277 municipal utilities and rural electric cooperatives. The leadership of the nine public power agencies works behind a confidentiality agreement with the leadership at the power plant to shield information about the financials, operational details, and decision-making process of the power plant. The decisions and efforts to invest in CCS at Prairie State are being made by few people, behind closed doors.

Carbon capture at the Prairie State Coal Plant is a boondoggle. PRI should be taking the lead on moving Illinois to a clean energy economy, not propping up the largest coal fired power plant in the state. We have an unprecedented opportunity to harness state and federal investments to build a clean energy economy in Illinois utilizing wind, solar, battery storage, microgrids, and demand response. Time and money spent on efforts to continue lighting things on fire to produce energy is precious time lost building the clean energy future we need to save the world from catastrophic climate change.

Andrew Rehn provides technical and policy expertise in support of Prairie River Network’s energy and coal pollution programs. He is passionate about water resources, energy policy, and coalition building. The Middle Fork is his favorite river to paddle.

764 total views, 1 views today